Warehouse Automation with AS/RS integration for Reserve Bank of India subsidiary BRBNMPL Currency Printing Press

THE CLIENT

Bharatiya Reserve Bank Note Mudran Private Limited (BRBNMPL) was established by Reserve Bank of India (RBI) as its wholly-owned subsidiary on 3rd February 1995 to augment the production of banknotes in India to enable the RBI to bridge the gap between the supply and demand for banknotes in the country.

The Corporate Mission of the Company is to produce banknotes conforming to international standards set by Central Banking and monetary authorities of the world and makes them available in adequate quantities to the Reserve Bank of India at competitive prices.

BRBNMPL WAREHOUSES

BRBNMPL has implemented the Automated Storage and Retrieval System (AS/RS) at its two currency printing presses in Mysore, Karnataka and Salboni, West Bengal. The present capacity for both the presses is 16 billion note pieces per year on a 2-shift basis.

Snapshot of Mysore & Salboni warehouses:

- 12,500 pallets capacity offering flexibility to store Raw Material and Paper

- 10 high double deep racking system

- 5 Aisles in ASRS for pallets system and each Aisle has one stacker crane to serve pallets and 5th aisle has no stacker crane but it is deployed using a transfer car

- Throughput of 40 pallets/hour

- The conveyors are used for both storage and retrieval process

- Barcode station is available to generate the barcodes for the pallets received

- 2 barcode scanning stations available to scan the pallets to validate

- Weighing station available to validate the weight of the inventory

CHALLENGES

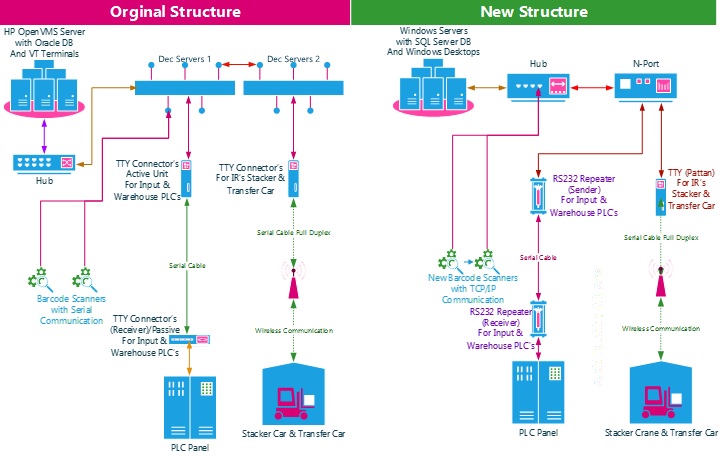

The infrastructure was 20 years old and all the systems were outdated including the software, PLCs, Servers, Networking Devices, etc. The requirement was to upgrade the entire solution and systems to the latest but integrating with the existing automation cranes, conveyors, optical sensors, weighing machine etc. The 20-year old software was developed in FORTRAN and the automation cranes were from efacec, Portugal. With not enough documentation and the ability to get support from the original suppliers, it was indeed a major challenge.

BRBNMPL called for a tender and out of the 11 bids, only SIERRA and the company that originally implemented the solution for BRBNMPL were qualified technically. After due consideration and diligence of SIERRA’s expertise in warehouse management and automation, BRBNMPL awarded the project to SIERRA. Winning this tender competing against a large corporate company who has been a leader in this space and also the original supplier is a significant achievement for SIERRA.

SOLUTION

- SIERRA’s WMCentral – Warehouse Management System (WMS) takes care of the inventory management needs of Warehouses covering the entire operations of the warehouse and helps in automating the same. The system allows automatic stack allocations for the incoming inventory, prints the barcode labels for easy/accurate identification, checks the positions of items once stacked, displays the positions automatically while issuing and provides for stock-taking features for periodic checking of inventory. Adequate reports are available for transaction tracking and there is also a visual display for AS/RS equipments live status tracking. This WMCentral solution was customized to meet BRBNMPL’s requirements and tender specifications in record time

- Application Components:

- Warehouse Operation

- Warehouse Control System (WCS)

- Programmable Logic Controllers (PLC) Operation

- The Warehouse Control System (WCS) was developed to achieve the following hardware integrations:

- The MOXA NPort serial communication device was used to communicate to the conveyor PLCs

- The crane and transfer crane PLC communication cannot be through hardwiring owing to the movement during operation and so it was managed by communicating through Infrared Optical Sensors (IR Sensing) connected to the NPort device

- The TCP/IP communication was used to communicate to the automation scanners, and weighing machines

- The Storage Process:

- On placing an incoming pallet in the weighing machine, the WCS system collects the weight of the pallets by integrating with the weighing machines

- The barcode labels are printed and stuck on the pallets and moved to the incoming conveyor

- The WCS reads the pallet id of the pallet placed in the conveyor with the help of the automation scanner that reads the barcode label

- The WCS communicates the same to the WMS and gets the storage location.

- The WCS then sends the movement commands to the conveyor PLC to move the conveyor and on reaching the storage area, the WCS sends the commands to the Crane PLCs via the IR communication sensor to place the pallet at a logically planned stack location.

- The Retrieval Process:

- On receiving inventory requests, the warehouse operator makes an issue entry in the WMS system

- The WMS system sends the retrieval request to the WCS System

- The WCS system activates the respective aisle crane to pick up the required pallet and then place it on the crane

- The automation scanner reads the barcode to validate the correctness of the pallet and then the conveyor is operated to move the pallet for issuing for production by the WCS system

- On a successful issue, it gets updated in the WMS system

- BRBNMPL also uses this system to store tools & spares apart from the raw materials and the system has options to do the transfer of pallets from one stack location to another etc.

- The purpose of the transfer crane is to shift the crane from one aisle to another aisle

- Omron supplied the latest PLC’s, the IT hardware was procured from DELL and the networking & other IT/communication infrastructure work was directly handled by SIERRA.

- SIERRA took care of the Project Management Control of the entire project and ensured that the project was successfully commissioned

| Infrastructure Upgrades | ||

| Old | New | Remarks |

| HP Alpha Server | DELL Server | Latest Server System |

| HP OpenVMS OS | Microsoft Windows Server | Latest OS |

| Oracle 7 | Microsoft SQL Server 2014 | Latest Database |

| DEC Server | MOXA NPort | Latest Device that supports RS232, RS422, RS485, TCP/IP in both half and full-duplex modes |

| VT Terminals | Windows 8 Desktops | Latest Desktop System |

| Standalone Barcode Printer | Network Barcode Printer | Barcode Printer with TCP/IP Protocol support |

| Standalone Barcode Scanner | Network Barcode Scanner | Barcode Scanner with TCP/IP Protocol support |

| TTY Connector | Latest TTY Connector | Latest TTY Connector with IR Device support |

| OMRON PLC | New OMRON PLC | Latest PLCs |

| — | SCAIME | Newly installed |

KEY BENEFITS

With SIERRA’s AS/RS integrated Warehouse Management Solution, BRBNMPL has successfully upgraded their 20-year old system to the latest technologies and took advantage of the intelligent WMS system with AS/RS integration to optimize the storage and retrieval operations of their warehouses.

- Complete peripherals are on the latest technologies

- Windows OS and latest software applications ensuring that it doesn’t get obsolete for another decade or two

- Graphical view of conveyer and aisle storage with drill-down options

- Robust and automatic backups in the backup server and tape drive

- Comprehensive solution allowing various mode of operation – Auto, Manual, Emergency with Reset & Refresh features

Added to the above, the efficiencies driven by the WMCentral WMS application were significant.

- Absolutely bug/error-free solution (Zero support calls in 4 years from go-live in 2016)

- Improved picking/delivery accuracy

- Highly optimized storage & retrieval operations

- Full visibility/accuracy of available Inventory

- Faster/error free automatic barcode scanning

- Storage operation throughput – 40 pallets/hour

- Retrieval operation throughput – 40 pallets/hour

Demonetization Period: This project went live in April 2016 in Mysore and May 2016 in Salboni. Once the demonetization was announced, the production was increased multi-fold and during the entire duration increased operation, there were zero support calls received for any software related issues. This is a significant achievement and a feather in the cap for our entire Warehouse Management Solutions team.