Processes

Picking

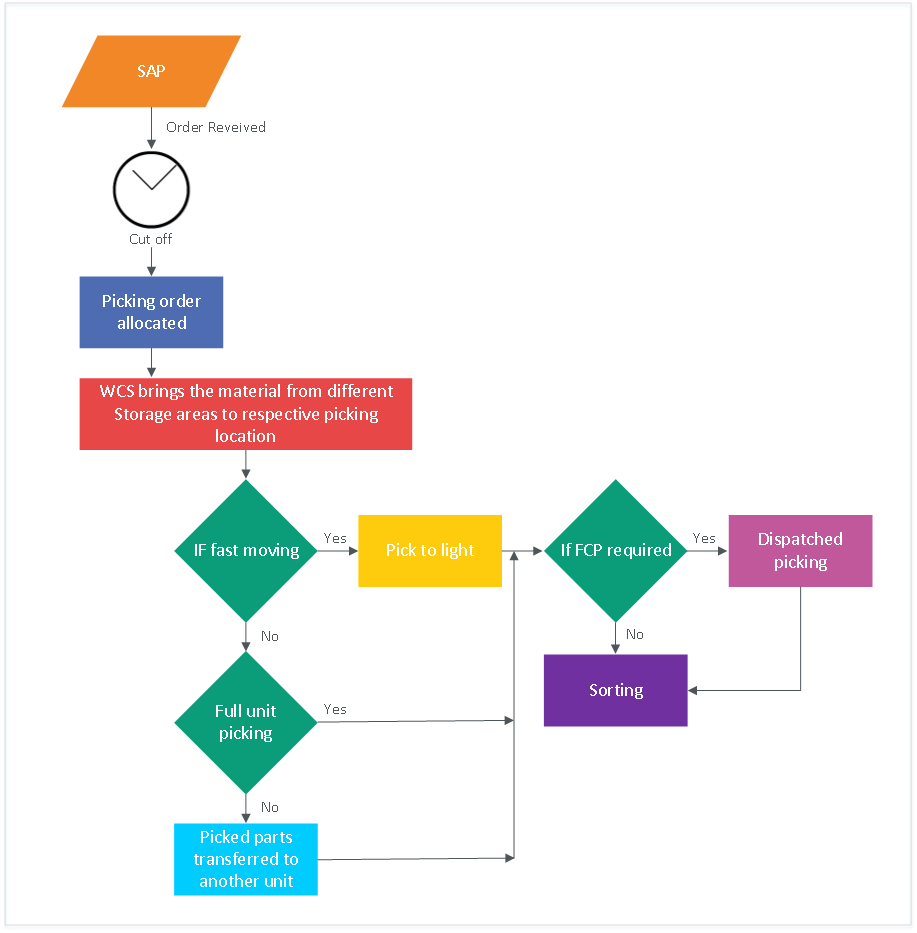

Pick materials from ASRS or manual storage area at the picking station by scanning the materials allocated for the normal delivery orders, very urgent orders, and export orders. Picking will happen based on the priority of deliveries and route planning.

- Based on the requirements received from ERP, a picking order shall be generated

- Units can be retrieved automatically from ASRS to the corresponding picking station based on picking orders

- Also, the system has features to retrieve the pallets to the picking station manually

- The system will allow partial picking and the picking order will be locked against the logged-in terminal for the users to pick the pouches from the source bin/pallet

- The picking process can be effected by different picking areas simultaneously

- The system retrieves the needed bins/pallets from ASRS, one by one optimally rather than all that is needed in the one-shot, which helps to keep the lines from getting clogged

- The system has the feature to book errors for the following categories,

- Short error

- Excess error

- Material damage

- Wrong part

- Packing damage

- For picking from fast-moving ASRS, the operator shall pick the parts from FM ASRS where pick-to-light is used for current retrieval order (based on the warehouse control system commands)

- Provision to pick multiple parts from the same destination bin

- Pick-to-Light (PTL)

- If the light in PTL does not work, the operator can still pick making use of the hand-held terminal (HHT). HHT can display locations from where the item can be picked. For FM picking, the system shall display the pending picking orders, crane status, and other details