Processes

Final Checking Packing process

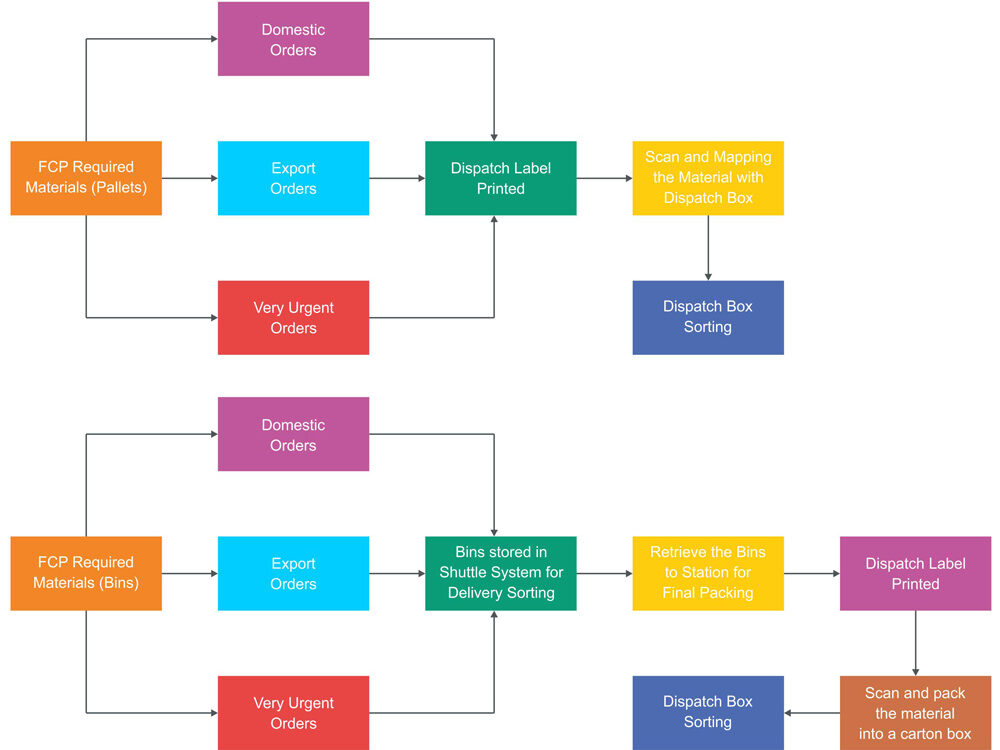

Pack the picked/packed materials into a final dispatch box and print the dispatch labels & group the materials delivery-wise. Packing will be based on the priority of the deliveries like normal delivery orders, very urgent orders, and export orders.

- The system has the provision to change the box size based on the size of the material (finished goods)

- The system has the provision to force close the dispatch if required

- The system has the provision to book the following errors,

- Material short

- Material excess

- Packing damage

- Wrong part

- Material damage

- The system has the provision to view the pending dispatch packing

- Bins can be retrieved from the packing station automatically based on the deliveries. The system has the provision to facilitate optimization of the required number of boxes in the final checking packing station

- The system has the provision to change the size of the packing group, i.e., The minimum number of bins of a delivery that needs to be consolidated in a uni-shuttle before releasing to a final packing station

- Strapping can be done in final checking packing station for all boxes

- The system also has the provision to do the final checking packing manually

- Dispatch labels (delivery-wise) shall be printed based on the bin arrived at the packing station