Processes

Packing Plan

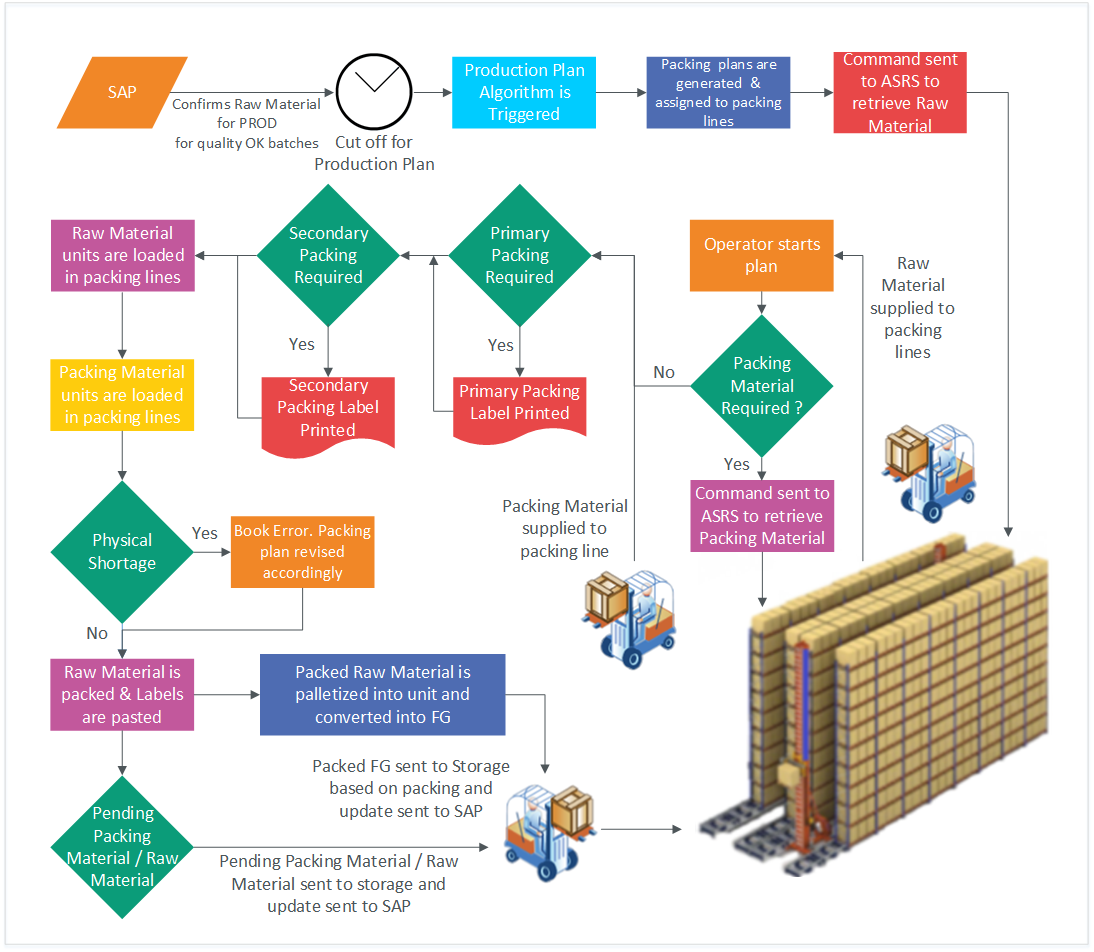

Create packing plans to convert raw materials into finished goods based on the available raw materials and order demand. The packing plans will be processed in the automatic packing and KIT lines for auto-packing, manual packing, and KIT packing.

- The system plans and allocates the available raw material based on demand for normal part or kit part and then for safety stock

- Plans can be generated for the allocated quantity based on their part MOQ value and then prioritized for packing by considering the open order types, order value, packing group, and receiving time of the raw materials

- It allows the packing supervisors to view and modify the packing plan generated and also modify the packing line to distribute the load in case the packing line is down. Packing plans are generated from the unpacked part to primary pack/secondary pack/repack for R&D/MRP change/MOQ change

The supply process helps to supply raw material/packing material as per the packing plan, simultaneously from either ASRS or a manual storage area.

- The system initiates the supply process automatically, once the packing plan is generated

- The system supplies the pallets from ASRS to packing lines based on the packing plan priority

- The system is optimized for supplying the pallets one by one rather than clogging the pallet supply path, which helps to improve the processes-throughput while reducing the storage problem at the packing line

- The system has display provisions to indicate to the operator when the pallets reach the delivery point of ASRS so that the operator knows that pallets are available at the packing lines

- It can also display the destination location of the pallets delivered at the discharge station by ASRS (destination sign), for the operator to view and transfer the pallet to the destination packing line, intimating the operator to transfer the unit to the packing line through a put-away notification. As the following process, the putaway screen in the handheld terminal shall display the pop-up message every 3 minutes until the suggested pallet is scanned at the station for further transport to the destination area

- The destination slip can be printed to denote the destination for the bin when a GPC unit is retrieved from bin ASRS

- The packing material requirement displays the open orders for supply of packing material to the packing lines which can typically be kept in PMs area or PM conventional area, for picking by the operator

Packing Plan